Explore EIDORADO

0

Export Countries

0

Years of Experience in Industrial Operation

0

Long Term Partner

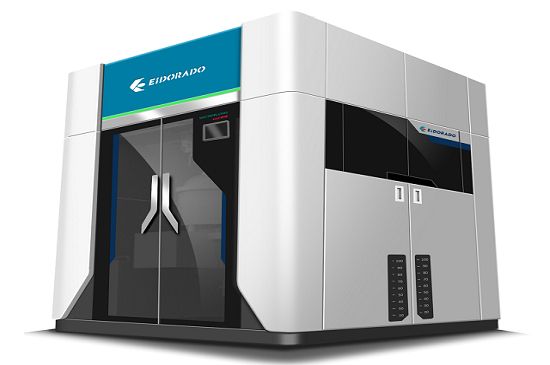

Electroplating and Surface Treatment Equipment

In addition to the high yield rate of the design process, it is also designed to save water and reduce waste. Breakthroughs in careful R&D and design, profound hardware production experience and perfect program control provide customers with the best production equipment.

Since its establishment in 1989, it has been engaged in the production, development and research of surface treatment equipment. With a strong team lineup, the most professional and excellent quality, it has created the most ideal equipment and constantly strives for excellence. During this period, it has won patents such as vibration electroplating device and improved electroplating drum structure. And obtained technology transfer from major German manufacturers KISSLER, LPW & BALSBEGR.

Main Products and Services

Provide customers with the most complete and exquisite services from electroplating equipment to wastewater treatment.

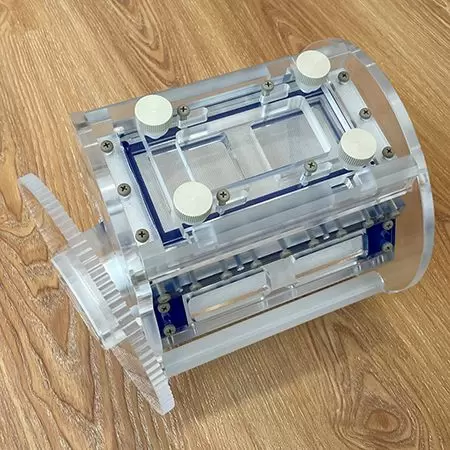

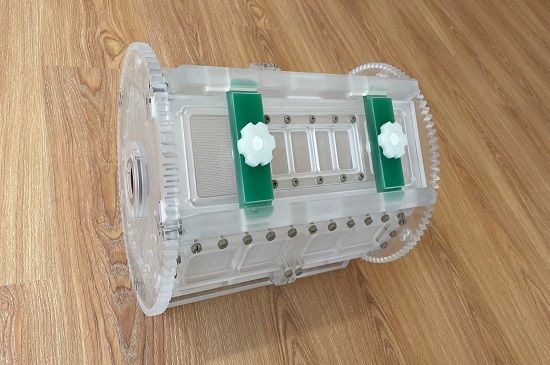

Important Role in Electroplating Peripheral Equipment

Electroplating drumThe electroplating drum is mainly used to immerse the workpiece in the electrolyte, a dn is placed in the drum to rotate so that its surface comes into contact with the metal ions in the electrolyte to achieve the electroplating process.

Dehydration and drying are completed at the same time, a good helper for electroplating

Dehydration dryerIt adopts two independent flip-up methods on the left and right, uses a Jpanese-made indirect hot air fan for heating, and the operation panel and air blower are integrated. The quality is stable and it has a constant temperature control device. It can operate continuously without anyone for 365 days.

High Plating Rete and Good Coating Uniformity

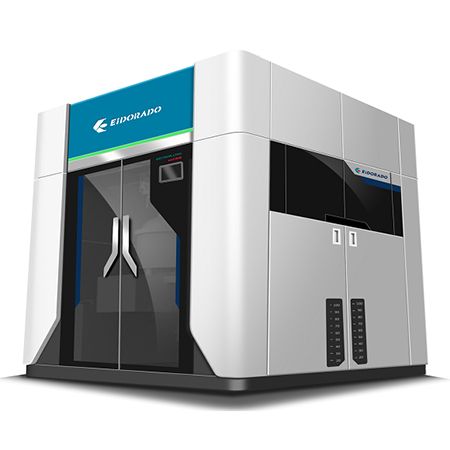

Barrel plating equipmentBarrel plating is an electroplating equipment suitable for plating small electronic parts. It saves space and labor costs, creates industrial profits, has excellent uniformity, and can shorten processing time.

High Efficiency and Low Emission Electroplating

Rotary plating machineIntroducing foreign advanced technology and cooperation, high-efficiency and low-emission electroplating can save more than 75% of production costs compared with traditional barrel plating, and the equipment maintenance is easy.