Electroplating Drum

EIDORADO CORP has outstanding patents and designs in electroplating drum equipment, and has won three patents including the improved structure of electroplating drums.

The most common problem with electroplating drums is clamping or deformation of workpieces. Our company has more than 20 years of experience in equipment construction and processing for the development, improvement and design of barrel plating, especially for small workpieces and drum door cover clamps. The material part has done its best to improve and provide supporting measures for solutions.

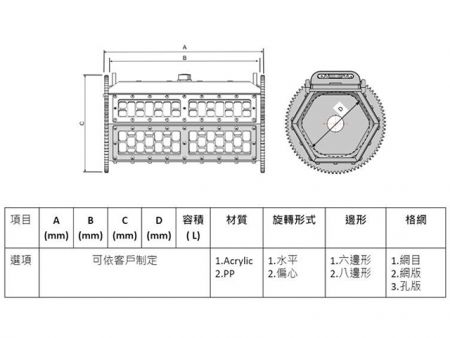

EIDORADO CORP can also customize the material, rotation form, edge shape, grid and other items of the roller according to the customer's conditions. If you want to know more about the roller manufacturing process and products, you can also contact us in person and visit the showroom, so that customers can better understand the process and products of the roller. Know the details and procedures clearly.

Product Features

There are many types of drums in electroplating equipment, mainly distinguished by factors such as the material used, shape and size. The following are some common roller types:

● Stainless Steel Roller: Stainless steel roller is one of the common types of rollers. It has the advantages of corrosion resistance, rust prevention, easy cleaning, etc., and is suitable for most electroplating processes.

● Plastic Roller: Plastic rollers are usually made of polypropylene (PP), polyvinyl chloride (PVC) and other materials. They have good acid and alkali resistance and cost advantages, and are suitable for some specific electroplating processes.

● Trapezoidal Drum: The trapezoidal drum is mainly used for electroplating large and heavy workpieces. Its shape can increase the contact area between the workpiece and the electrolyte to achieve better processing results.

● Rotating Drum: A rotating drum is a drum that can rotate in both horizontal and vertical directions. It is usually used for electroplating small, complex-shaped workpieces and can achieve a full range of processing effects.

● Vibrating Drum: A vibrating drum is a drum that can vibrate in both horizontal and vertical directions. It is usually used for electroplating small, elongated workpieces to achieve better processing results.

When choosing a roller, you need to choose according to actual needs. Choosing a suitable roller can improve the efficiency and quality of the electroplating process.

Equipment Structural Characteristics

The drum in electroplating equipment is a piece of equipment used in the electroplating process. It is mainly used to immerse the workpiece in the electrolyte so that its surface can be electroplated.

The roller is usually made of stainless steel or plastic, which is anti-corrosion, wear-resistant, corrosion-resistant and can maintain stable performance over a long period of use.

During the electroplating process, the workpiece is placed in a drum, and then the drum is rotated so that its surface comes into contact with the metal ions in the electrolyte to achieve the electroplating process. By controlling the rotation speed of the drum and the composition of the electrolyte, different treatment effects on the workpiece surface can be achieved.

The drum can also adjust the temperature during the electroplating process by heating or cooling to achieve better processing results. When selecting a drum, factors such as the size and shape of the workpiece and the type of metal that needs to be processed during the plating process need to be considered.

Application

1. Surface Treatment: The roller can be used to form a uniform film on the metal surface to improve the properties of the metal surface, such as anti-corrosion, wear resistance, etc.

2. Precision Machining: Rollers can also be used for precision machining, such as making micro parts, micro gears, etc.

3. Preparation of Nanomaterials: The roller can be used to prepare nanomaterials, such as nanoparticles, nanowires, etc.

4. Production of Solar Cells: Rollers also have important applications in the production process of solar cells. They can be used to deposit uniform metal films on substrates to improve the conversion efficiency of solar cells.

In short, as an important component in barrel plating equipment, the roller has broad application prospects.

How Are Advanced Electroplating Drums Enhancing Semiconductor Component Processing?

Semiconductor manufacturing demands the highest precision in surface treatment. EIDORADO's electroplating drums deliver exceptional results for critical applications including anti-corrosion treatments, wear resistance enhancement, and preparation of nanomaterials essential to semiconductor production. Our rotating and vibrating drum technologies ensure uniform plating coverage even on complex geometries, while maintaining the strict quality standards required in semiconductor processing.

Our comprehensive electroplating drum lineup includes corrosion-resistant stainless steel models, chemical-resistant plastic options, specialized trapezoidal designs for heavier workpieces, and advanced rotating and vibrating drums for complex geometries. Each system is built to exacting standards, ensuring consistent performance in demanding semiconductor and PCB manufacturing environments. EIDORADO's electroplating drums support diverse applications including anti-corrosion treatment, wear resistance enhancement, precision component manufacturing, nanomaterial preparation, and solar cell production processes.