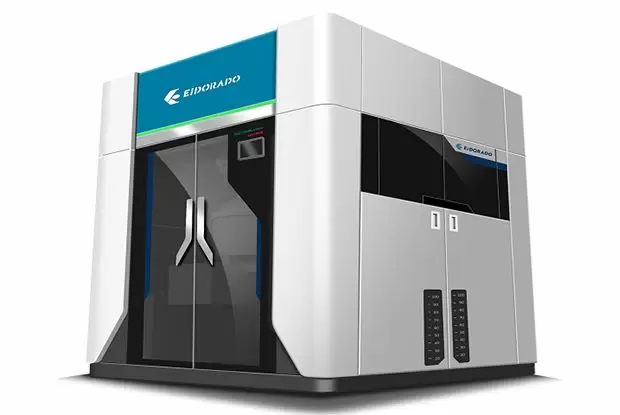

Automated Anode Treatment Equipment

Anodizing Equipment, Aluminum Alloy Anode Treatment Equipment, Aluminum Anodizing Equipment, Hard Film Anode Equipment, Anodizing Equipment

EIDORADO CORP Automated anode equipment, including automated scheduling, can optimize production efficiency to the greatest extent, and can also be mixed and put into production according to the actual production needs of customers. The customized process eliminates the need for downtime adjustments in the process, and can also significantly reduce the manpower requirements of customers and the process. , thereby saving labor consumption costs.

It can be used in the electronics industry such as mobile phone, laptop or tablet casings, and can also be used in various precision components in the aerospace industry. It can effectively prevent the aluminum surface from being oxidized again, improve the surface hardness, and enhance the appearance and texture of the product.

The automated program records production history and real-time monitoring, and can also arrange the required manufacturing conditions for each workpiece, so on-site operators can quickly get started.

Product Features

- High plating efficiency.

- Stable rectifier current output.

- Paperless process monitoring and recording system.

- Connect with MES system data to achieve Industry 4.0 goals.

- PLC human-machine control interface, environmentally friendly and energy-saving, structural design saves manpower, and operation is ergonomic.

Institutional Design

Presented Using Columns:

1. Hardware equipment: water-saving design, target swing transmission design, overhead crane movable water tray, aeration cleaning spoiler, European standard waterproof transfer box...etc.

2. Software design: digital slot identification, remote online inspection and repair, process history record, BarCode parameter record...etc.

Application

The main application areas of anodizing treatment:

1. Surface Treatment of Aluminum Materials: Anodizing is one of the main methods of anodizing the surface of aluminum materials. This treatment can form an oxide layer on the surface of the aluminum material, which can improve the corrosion resistance and surface hardness of the aluminum material.

Surface Treatment of Steel Materials: Anodizing can form an oxide layer on the surface of steel materials. This oxide layer can improve the corrosion resistance, surface hardness and wear resistance of the steel.

2. Pre-plating Treatment: Before electroplating, the metal surface usually needs to be treated so that the plating layer can adhere better. Anodizing is a commonly used pre-plating treatment method.

3. Printed Circuit Board Manufacturing: During the printed circuit board manufacturing process, anodizing can be used to remove the oxide layer on the surface of the copper material, thereby improving the connectivity of the printed circuit board.

4. Titanium Nitrate Treatment: Anodic treatment can be used for titanium nitrate treatment to form a titanium oxide layer on the metal surface. This oxide layer can improve the wear resistance and corrosion resistance of the metal surface.

5. Food Processing: Anodizing can be used in food processing. For example, anodizing certain fruits and vegetables can extend their shelf life.

Can Anodizing Equipment Adapt to Rapidly Changing Mobile Device Production Schedules?

EIDORADO's automated scheduling system is specifically designed for the fast-paced mobile device industry, allowing manufacturers to seamlessly mix production batches without downtime for process adjustments. Our equipment can transition between different aluminum alloy components and finish specifications in minutes rather than hours, reducing labor costs while maintaining consistent quality across diverse product lines. Schedule a consultation to learn how our flexible anodizing solutions can optimize your mobile device production.

The comprehensive digital infrastructure of our anodizing systems includes paperless monitoring, production history recording, and real-time parameter tracking that seamlessly integrates with MES systems to achieve Industry 4.0 objectives. Each unit comes equipped with a user-friendly PLC human-machine interface that enables operators to quickly master the system, while the stable rectifier current output ensures consistent, high-quality surface treatments. Whether processing mobile phone casings, laptop components, or precision aerospace parts, EIDORADO's anodizing equipment delivers superior performance with environmentally conscious operation.