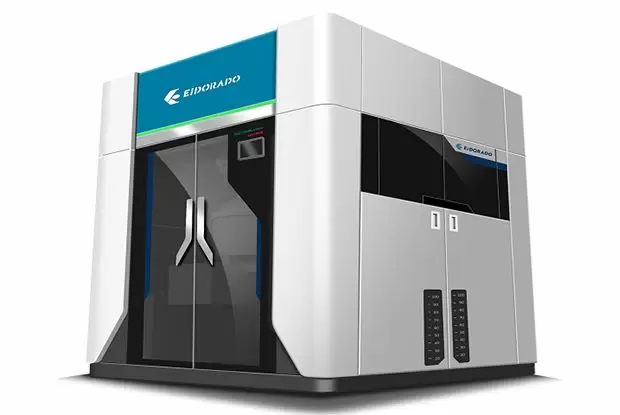

Electroplating Peripheral Equipment - Anode Cleaning Machine

The anode cleaning machine of EIDORADO CORP is highly recognized by customers. The equipment used by our company has good cleaning effect. When the workpiece is rotated and cleaned in the drum, it can effectively clean and treat the metal surface, improving surface quality and corrosion resistance.

Our company's anode cleaning machine is highly efficient and energy-saving. It uses electrochemical reaction for cleaning. Compared with traditional mechanical cleaning methods, it can save a lot of energy and water resources.

It has a high degree of automation and has functions such as automatic feeding, automatic cleaning, and automatic discharge, which improves production efficiency and reduces labor costs.

The use of high-quality components and control systems enables stable operation for a long time, reduces failure rates and maintenance costs, and has high reliability. This is also the main factor why customers are very willing to cooperate with Yidu Enterprises.

Product Features

Anode cleaning machines are usually used in processes such as anodizing and electroplating. They can clean and treat metal surfaces by immersing metal parts in electrolytes containing chemical cleaning agents and forming an oxide layer or coating on the metal surface through the action of electric current. Purpose.

Anode cleaning machines usually consist of one or more cleaning tanks, power supply, control system and accessories. When using an anode cleaning machine, the operator needs to soak the metal parts to be cleaned in the cleaning tank and turn on the power supply to allow current to pass through the metal parts and electrolyte, thereby producing an oxide layer or plating layer. After cleaning is completed, the operator needs to remove the metal parts from the cleaning tank and perform subsequent processing or processing.

Anode cleaning machines are widely used in industrial processes such as metal surface treatment, electroplating, and anodizing. They can improve the quality and corrosion resistance of metal surfaces and extend the service life of metal parts.

It is equipped with a horizontal PP roller and is equipped with a roller lifting motor and a transmission motor. It is easy to operate, can effectively save manpower and improve work efficiency.

● Good Cleaning Effect: The anode cleaning machine can form an oxide layer or coating on the metal surface, which can effectively clean and treat the metal surface and improve surface quality and corrosion resistance.

● Efficient and Energy-Saving: The anode cleaning machine uses electrochemical reaction for cleaning, which can save a lot of energy and water resources compared with traditional mechanical cleaning methods.

● High Degree of Automation: The anode cleaning machine can realize automated control and has functions such as automatic feeding, automatic cleaning, and automatic discharge, which can greatly improve production efficiency and reduce labor costs.

● Easy to Operate: The operation of the anode cleaning machine is simple and easy to understand. Just follow the operation manual to complete the task of cleaning and treating the metal surface.

● High Reliability: The anode cleaning machine uses high-quality components and control systems, has good reliability and stability, and can operate stably for a long time, reducing failure rates and maintenance costs.

To sum up, the anode cleaning machine has the characteristics of good cleaning effect, high efficiency and energy saving, high degree of automation, easy operation and high reliability. It is an indispensable equipment in metal surface treatment and manufacturing process.

Institutional Design

1. The body of the anode cleaning machine is made of PP, and the frame is made of stainless steel.

2. It has a movable and liftable unloading tray, and the opening of the unloading tray can directly guide materials into the titanium basket.

Application

1. Metal Processing Industry: It is widely used in the metal processing industry and can be used to clean and treat metal parts, tools, machines and other products, thereby improving their surface quality and corrosion resistance and enhancing their mechanical properties.

2. Electroplating Industry: It can be used for surface treatment before electroplating to improve the adhesion and uniformity of electroplating by removing dirt and oxide layers on the metal surface, making the electroplated layer more stable and durable.

3. Automotive Industry: It can be used for surface treatment of auto parts to improve their quality and corrosion resistance, enhance their mechanical properties, and ensure the safety and reliability of the car.

4. Aerospace Industry: It can be used for surface treatment of aerospace parts to improve their surface quality and corrosion resistance, enhance their mechanical properties, and ensure the safety and reliability of aerospace vehicles.

5. Food Processing Industry: It can be used in the food processing industry to clean and disinfect stainless steel containers, pipes, equipment, etc., thereby ensuring food safety and hygiene standards.

In short, anode cleaning machines are suitable for various industries that require cleaning and treatment of metal surfaces, and play an important role in improving product quality and competitiveness.

How can automated anode cleaning improve semiconductor manufacturing efficiency?

EIDORADO's automated anode cleaning machines dramatically increase semiconductor production throughput by eliminating manual handling processes. With automatic feeding, cleaning, and discharge capabilities, our systems reduce cycle times by up to 40% while ensuring consistent, high-quality surface treatment essential for semiconductor component reliability. This automation allows your skilled technicians to focus on higher-value tasks while reducing the risk of human error in critical cleaning processes.

Distinguished by its high degree of automation, our Anode Cleaning Machine features advanced capabilities including automatic feeding, cleaning, and discharge functions that dramatically improve production efficiency while minimizing labor costs. The equipment's user-friendly operation, combined with premium components and sophisticated control systems, ensures remarkable reliability with minimal downtime and maintenance requirements. Widely deployed across semiconductor, PCB, automotive, aerospace, and metal processing industries, EIDORADO's Anode Cleaning Machine stands as an essential solution for organizations seeking to enhance surface quality, improve corrosion resistance, and extend the service life of critical metal components.