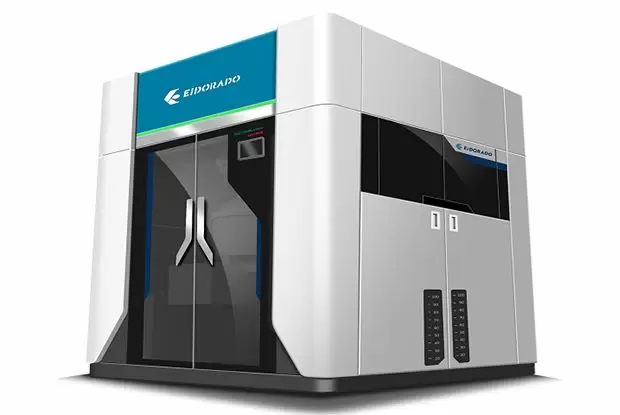

Electroplating Cleaning Equipment

Electroplating Cleaning Machine

The electroplating cleaning equipment of EIDORADO CORP is a kind of equipment specially used to clean and pre-treat metal workpieces and components required in the electroplating process.

The main appeal is energy-saving design:

(Material) Materials are not wasted: Strength stress analysis ensures the stability of material use and extends its service life.

(Water) Circulating water is reused: Designed with connected troughs to save water, materials and space.

(Electricity) Does not use excess electricity: The temperature control system accurately reaches the usage temperature without excessive (continuous) heating and standby power saving mode.

Product Features

Electroplating is a process that electrolytically deposits a layer of metal coating on a metal surface. It is often used for protection, beautification, and enhanced wear resistance. Before electroplating, the metal surface needs to be cleaned and pre-treated to ensure that the metal surface is clean, flat and uniform, so as to obtain good coating quality.

The use of electroplating cleaning equipment can improve the quality and efficiency of electroplating and reduce product defects and waste. Operating procedures and safety requirements must be strictly followed during use to prevent safety accidents.

● Versatility: Cleaning equipment includes a variety of cleaning equipment, such as oil cleaning machines, pickling machines, alkali cleaning machines, etc., which can clean and pretreat different metal surfaces to meet different electroplating process requirements.

● High Degree of Automation: Many electroplating cleaning equipment adopts advanced automation technology, which can realize automated cleaning and pretreatment, reduce manual operations, improve production efficiency, and ensure consistency and traceability.

● Environmental Protection and Energy Saving: Electroplating cleaning equipment can achieve efficient, energy-saving, low-pollution cleaning and pretreatment, effectively reduce pollutant emissions and energy consumption, and achieve green and environmental protection purposes.

● Stable Quality: Electroplating cleaning equipment can achieve stable production quality, reduce product defect rates and waste, and improve product competitiveness while ensuring cleaning and pretreatment effects.

● Safe and Reliable: Electroplating cleaning equipment is designed and manufactured with full consideration of safety and reliability issues, and is equipped with various safety protection devices and detection systems to ensure the safe and stable operation of the equipment.

Institutional Design

The structural design of electroplating cleaning equipment mainly includes cleaning tanks, pumps, filters, sprinklers, heating devices, water circulation devices, etc.

1. Cleaning Tank: The most basic mechanism design in electroplating cleaning equipment is the cleaning tank, whose main function is to hold cleaning fluid. The size, shape and material of the cleaning tank will all affect the cleaning effect and durability.

2. Pump: The pump is a mechanism used to pump the cleaning fluid out of the cleaning tank and spray it onto the surface of the object to be cleaned. The performance of the pump will affect the cleaning effect and production efficiency.

3. Filter: In order to prevent impurities and solid particles in the cleaning fluid from contaminating the object to be cleaned, a filter is usually installed at the pump outlet to filter impurities and solid particles in the cleaning fluid.

4. Sprinkler Head: The sprinkler head is a mechanism that achieves cleaning by spraying cleaning fluid onto the surface of the object to be cleaned. The design of sprinkler heads usually takes into account factors such as flow rate, spray angle and spray position.

5. Heating Device: The heating device is used to heat the cleaning fluid to improve its cleaning effect. The form and performance of the heating device depend on the characteristics of the cleaning fluid and the operating temperature requirements.

6. Water Circulation Device: The water circulation device is used to recycle cleaning fluid and save water and cleaning agents. It mainly includes water pumps, water pipes, water storage tanks and other components to realize the recycling of cleaning fluid.

Application

1. Semiconductor Industry: Used to clean the surface of semiconductor materials and remove surface contaminants to improve manufacturing efficiency and product quality.

2. Electronic Industry: Used to clean the surface of electronic products such as circuit boards and IC chips to remove welding residues and other contaminants to improve product reliability and performance.

3. Automotive Industry: Used to clean the surface of auto parts and remove contaminants such as oxides, grease and dust from steel, aluminum alloys and other materials to improve the surface quality and durability of auto parts.

4. Aviation and Aerospace Industry: Used to clean the surfaces of aviation and aerospace devices such as engine parts and fuselage parts, and remove oxides and dirt from materials such as aluminum and magnesium alloys to improve the reliability and safety of the devices.

5. Medical Industry: Used to clean the surface of medical devices and remove blood, bacteria and other contaminants to ensure the hygiene and safety of medical devices.

How Can Semiconductor Manufacturers Reduce Environmental Impact While Improving Cleaning Efficiency?

EIDORADO's electroplating cleaning systems address this challenge through our triple-efficiency design that conserves materials through stress-optimized components, recycles water via connected trough systems, and reduces electricity consumption with precision temperature control. Our semiconductor clients report up to 30% reduction in resource consumption while achieving superior surface preparation quality, essential for high-yield semiconductor manufacturing processes.

Our electroplating cleaning solutions encompass versatile cleaning capabilities including oil removal, pickling, and alkali cleaning processes to meet diverse manufacturing requirements. With a focus on environmental sustainability and production efficiency, these systems significantly reduce pollutant emissions while maintaining consistent, high-quality results. The comprehensive structural design incorporates advanced pumping systems, precision filtration, optimized sprinkler configurations, and intelligent heating mechanisms to ensure reliable operation and superior cleaning effectiveness for critical applications in electronics, automotive, aerospace, and medical device manufacturing.