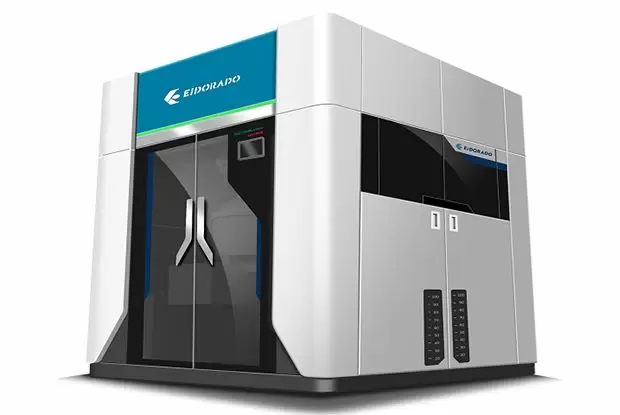

Electroplating EN Equipment

The design features of EIDORADO enterprise electroplating EN equipment are the swing of the workpiece in the plating tank, the circulation of the liquid in the plating tank, the use of overflow design, the temperature of the plating tank at 90 degrees C, the combination of the automatic dosing system, and the tank design (stainless steel rounded corner tank, partition water (indirect) heating) and anti-leaching design.

Since competitors in the same industry rarely focus on the process of electroplating EN equipment, the reason why they choose EIDORADO CORP Enterprises to make electroplating EN equipment is because the company's design features are very suitable for customers' production capacity needs, and they will further optimize the advantages of this product and seize the opportunity. Customer demand for cooperation.

Product Features

● Precision: Equipped with a high-precision control system to ensure the stability and quality of the process.

● Reliability: Reliability to ensure stability and reliability over long periods of time.

● Adaptability: Highly adaptable to adapt to different process requirements and applications.

● Safety: High safety to ensure the safety of operators and the environment.

● Automation: High degree of automation to improve production efficiency and reduce labor costs.

● Scalability: Highly scalable to meet future expansion and upgrade needs.

● Environmental Protection: It has high environmental protection to reduce the impact on the environment.

In short, the characteristics of electroplating EN equipment need to be customized and designed according to different applications and needs to ensure that it can meet process requirements and improve production efficiency.

Institutional Design

1. Plating Tank: Responsible for containing electrolyte and metal plating solution for use in the manufacturing process.

2. Power Supply System: Responsible for providing appropriate voltage and current to promote the reduction and deposition of metal ions in the electrolyte onto the surface of the plated object.

3. Electrode System: Responsible for transmitting current to the surface of the object to be plated during the electroplating process.

4. Regulation System: Responsible for monitoring and controlling various parameters of the entire electroplating process, such as voltage, current, temperature, pH value, etc., to ensure the stability and quality of the process.

5. Filtration System: Responsible for filtering the electrolyte and metal plating solution to remove impurities and contaminants to ensure the stability and quality of the process.

Application

1. Automobile Industry: It can be used for chrome plating, zinc plating, copper plating, etc. of automobile parts to increase corrosion resistance and aesthetics.

2. Aerospace Industry: It can be used for nickel plating, chromium plating, etc. of aerospace parts to improve corrosion resistance and wear resistance.

3. Electronic Industry: It can be used for gold plating, tin plating, etc. of electronic components to improve conductivity and anti-corrosion.

4. Jewelry Industry: It can be used for gold plating, silver plating, etc. on jewelry to improve the beauty and durability.

5. Mechanical Industry: It can be used for chrome plating, copper plating, etc. of mechanical parts to improve wear resistance and corrosion resistance.

6. Chemical Industry: It can be used for nickel plating, chromium plating, etc. on chemical containers to improve corrosion resistance and pressure resistance.

In short, electroplating EN equipment plays an important role in various industries and applications, not only improving product quality and durability, but also improving production efficiency and reducing costs.

How Can Precision Control Systems Improve Yield Rates in Semiconductor Electroplating?

EIDORADO's high-precision control systems for EN electroplating deliver consistent layer thickness with ±2% tolerance, significantly reducing defect rates in semiconductor manufacturing. Our customers report up to 15% improvement in first-pass yield when upgrading to our advanced systems with real-time parameter monitoring and automated adjustments. Contact us to learn how our precision electroplating solutions can optimize your semiconductor production processes.

What distinguishes EIDORADO's Electroplating EN Equipment in the market is our specialized focus on process optimization that competitors rarely address. Our systems are meticulously designed to meet specific production capacity requirements with high-precision control systems that ensure process stability and consistent quality. From the automotive and aerospace industries to electronics manufacturing, our equipment delivers superior corrosion resistance, wear protection, and conductivity enhancement while maintaining environmental compliance through our advanced filtration systems and sustainable design principles that align with our commitment to creating a greener future.