Electrophoresis Equipment

Electroplating electrophoresis equipment is a kind of equipment that combines electroplating technology and electrophoresis technology. It is mainly used for metal surface treatment and surface modification.

In the process of electroplating and electrophoresis, the metal substrate is placed in the electrolyte as the anode, and the metal ions are placed in the electrolyte as the cathode. By applying an external voltage, the metal ions are reduced and deposited on the surface of the metal substrate, thereby achieving metal Surface plating.

At the same time, electrophoresis equipment can also use electrophoresis technology to modify the surface of the plating layer. For example, by adding specific molecules during the electrophoresis process, the molecules can be adsorbed on the surface of the coating layer, thereby changing its chemical properties, surface energy, biocompatibility and other characteristics, expanding its application scope.

Product Features

- Efficiency: Electrophoresis equipment can achieve metal plating and surface modification at the same time, greatly improving product production efficiency.

- High Precision: By controlling parameters such as voltage, current, and time, high-precision control of metal plating thickness and uniformity can be achieved.

- High Quality: Electroplating and electrophoresis equipment can realize the integrated process of metal plating and surface modification, thus ensuring the quality and stability of the product.

- Environmental Protection: Compared with traditional chemical plating methods, electroplating and electrophoresis equipment can save metal resources and protect the environment.

- Flexibility: By adjusting the parameters of electroplating and electrophoresis equipment, products of different shapes, sizes, and materials can be plated and surface modified.

Institutional Design

1. Plating Bath: The plating bath is the main component of electroplating and electrophoresis equipment. It is used to load the plating bath and the objects to be plated. The material of the plating bath is generally made of materials that are not easily corroded by the plating bath, such as PVC, PP, etc.

2. Power Supply Unit: The power supply unit is used to provide the voltage and current required by the equipment to drive the metal ions in the plating solution to deposit on the surface of the object to be plated.

3. Cathode: The cathode is an important component in electroplating and electrophoresis equipment. It is used to load metal ions in the plating solution and reduce the metal ions to metal and deposit it on the surface of the object to be plated by applying an external voltage.

4. Anode: The anode is another important component in electroplating and electrophoresis equipment. Metal materials are generally selected as the anode to release ions in the plating solution and keep the concentration of metal ions in the plating solution stable.

5. Control System: The control system is the core of electroplating and electrophoresis equipment. It is used to control components such as the plating bath, power supply unit, cathode and anode, and to adjust and control parameters such as the temperature, concentration, voltage, and current of the plating solution.

In short, the structural design of electroplating and electrophoresis equipment is a complex system engineering that needs to consider multiple factors, such as the reliability, stability, and service life of the equipment, to meet the needs of different users for product quality and production efficiency.

Application

1. Automobile Industry: The automobile industry is one of the main application fields of electroplating and electrophoresis equipment. Coating the surface of automobile parts with a metal film can improve their corrosion resistance, wear resistance and aesthetics. Common coating materials include zinc, chromium, nickel, etc.

2. Electronic Industry: The electronic industry is another important application field of electroplating and electrophoresis equipment. In the production process of electronic components, metallization of parts is often required to protect circuit boards and electronic components from damage. Electroplating and electrophoresis technology can achieve precise plating of electronic components and improve product quality and reliability.

3. Mechanical Industry: The mechanical industry is also one of the application fields of electroplating and electrophoresis equipment. In the production process of mechanical parts, metal surface treatment is often required to improve its corrosion resistance, wear resistance and surface hardness. Common plating materials include nickel, chromium, copper, etc.

4. Household Appliances: Household appliances are another application area of electroplating and electrophoresis equipment. Common household appliances such as electric pots, electric kettles, induction cookers, etc. often require metal plating on their surfaces to increase their service life and aesthetics.

Electrophoresis equipment is widely used in electronics, automobiles, aerospace, chemical industry, biomedicine and other industries, and plays an important role in improving the corrosion resistance, surface hardness, wear resistance, biocompatibility and other properties of metal materials.

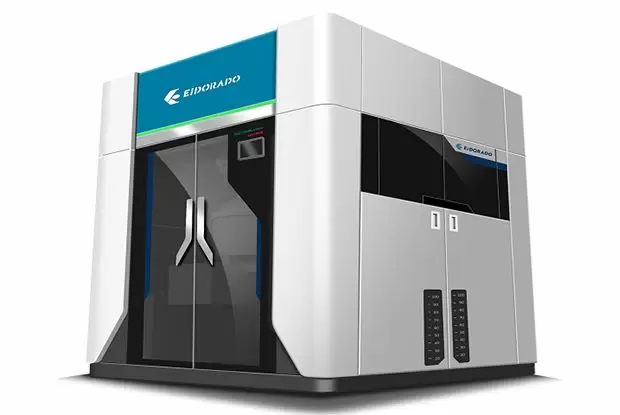

Why Are Leading PCB Manufacturers Switching to Integrated Electroplating and Electrophoresis Systems?

The answer lies in productivity and versatility. EIDORADO's dual-function equipment allows PCB manufacturers to perform both metal plating and surface modification in a single process, cutting production time by up to 40%. Our systems accommodate varying board sizes and complexity with minimal reconfiguration, supporting high-mix production environments. With precise control over plating thickness down to the micron level and the ability to modify surface properties for specific applications, our equipment delivers the flexibility modern PCB manufacturing demands. Connect with our experts to calculate the efficiency gains possible for your specific production line.

With over 30 years of industry experience since our establishment in 1989, EIDORADO has engineered our Electrophoresis Equipment to address the growing demands for environmentally responsible manufacturing processes. Our systems utilize resource-efficient technology that minimizes metal waste while maximizing coating performance. The comprehensive control system allows for flexible operation across different production requirements, from small batch processing to high-volume manufacturing, making it an ideal solution for companies seeking to enhance their surface treatment capabilities while meeting stringent environmental standards.