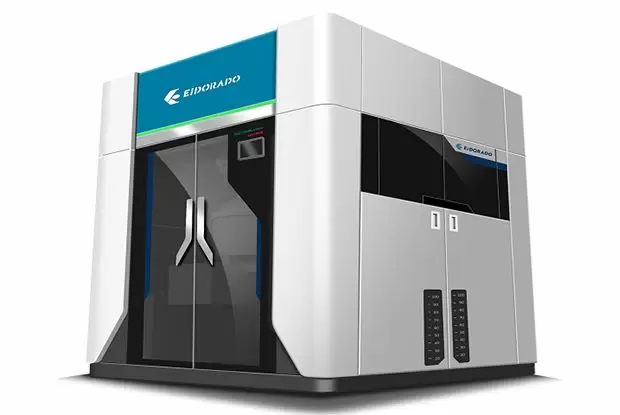

Ion Plating Equipment

EIDORADO CORP ion plating equipment technology is ahead of competitors in the industry in the field of PVD surface treatment technology, with the following characteristics:

● Vacuum coating surface treatment equipment cooperates with foreign technologies and introduces low-temperature ion plating technology.

● Apply ion plating technology to expand the automotive parts and consumer product markets.

The operators of EIDORADO CORP must receive appropriate training and be familiar with the operating procedures and safety precautions of the equipment. Secondly, parameters such as heating, vacuum degree and gas flow of the equipment must be strictly controlled to ensure the stability and quality of the process. Finally, we must pay attention to the maintenance and upkeep of the equipment and replace consumable parts in time to extend the life of the equipment and improve work efficiency. Through the above characteristics, we can gain industry opportunities and advantages.

Product Features

By attaching metal ions to the surface of the object, a uniform metal film is formed. This technology can improve the corrosion resistance, wear and appearance of the material.

Ion plating equipment mainly consists of four parts: ion source, vacuum chamber, substrate rack and control system. Among them, the ion source is used to generate the required metal ions, the vacuum chamber is used to create a low-pressure environment to reduce oxidation reactions and other adverse effects, and the substrate rack is used to place objects that require surface treatment. The control system is responsible for controlling heating, gas pressure, electron beam and other parameters to ensure the stability and controllability of the process.

● Efficiency: Ion plating technology can produce high-quality metal coatings in a short time, so it is highly efficient.

● Uniformity: Due to the existence of ion exchange membrane, ion plating technology can produce uniform metal coating, avoiding some uneven phenomena that may occur in traditional metal plating technology.

● Controllability: By adjusting plating parameters, such as plating time, current density and plating solution concentration, the thickness, hardness, morphology and other characteristics of the metal coating can be controlled.

● Environmental Protection: Compared with other metal plating technologies, ion plating technology has lower pollution emissions and is more environmentally friendly.

● Versatility: Ion plating technology can be applied to the manufacture of different metal coatings and can achieve coatings of different colors and thicknesses.

● Cost-Effectiveness: Compared to other metal plating technologies, ion plating technology has lower costs because it enables efficient, uniform and controllable metal plating manufacturing.

Institutional Design

1. Electroplating Tank: The electroplating tank is one of the main components of the entire equipment. It is usually made of corrosion-resistant materials such as polypropylene or glass. Its size and shape depend on the size and shape of the substrate to be plated.

2. Ion Exchange Membrane: Ion exchange membrane is a key component used to control the movement of ions, usually a polymer material, such as sodium polyacrylate or polytetrafluoroethylene.

3. Electrodes: Electrodes are the components that produce electrical current, usually made of metal such as platinum or copper. The shape and number of electrodes depends on the size and shape of the plating tank.

4. Power Supply: A power supply is a device that provides voltage and current. Common ones include DC power supply and AC power supply. The capacity of the power supply depends on the required current and voltage.

5. Temperature Control System: In order to ensure the stability of the electrolyte and the quality of the plating layer, the temperature in the electroplating tank needs to be controlled. Typically, a water or oil cooling system or a heating system can be used to control the temperature of the plating tank.

6. Automatic Control System: In order to achieve automation and precise control of the electroplating process, an automatic control system can be installed, such as a PLC (programmable logic controller) or a microprocessor controller. These systems control parameters such as current, voltage, temperature and time in the electroplating bath to achieve high-quality coating manufacturing.

7. Safety Measures: In order to ensure the safety of operators, some safety measures can be installed on the equipment, such as leakage circuit breakers, automatic power-off systems and alarm systems. These measures can effectively protect the safety of operators.

Application

1. Metal Processing: Can be used to improve the surface properties of metal parts, such as corrosion resistance, wear resistance and electrical conductivity. This is particularly important for metal parts that require high precision, strength and durability, such as in the aerospace and automotive industries.

2. Electronics: Metal components such as circuit boards, connectors, and wires that can be used to make electronics. It can increase the conductivity, corrosion resistance and wear resistance of metal parts, thereby improving product performance and reliability.

3. Medical Devices: Can be used to improve the surface properties of medical devices, such as corrosion resistance, biocompatibility and sliding properties. This is especially important for medical devices that require a high degree of reliability and durability, such as artificial joints and dental implants.

4. Plastic Products: Metalized components that can be used to make plastic products, such as plastic electronic product casings, vehicle casings, etc. It increases the appearance and wear resistance of metal parts.

5. Optical Products: Can be used to improve the surface properties of optical products, such as reflectivity, transmittance and anti-reflection. It is especially important for optical products that require high precision, high transparency and high performance, such as lenses, lenses and optical filters.

How Can Low-Temperature Ion Plating Enhance Semiconductor Component Performance?

EIDORADO's low-temperature ion plating technology solves critical challenges in semiconductor manufacturing by enabling precise metal film deposition without thermal damage to sensitive components. Our systems achieve uniform coatings at temperatures significantly lower than conventional methods, preserving substrate integrity while enhancing conductivity, corrosion resistance, and wear protection. Contact us to discover how our advanced PVD solutions can improve your semiconductor production yield and component reliability.

The technology delivers exceptional value through six key advantages: superior efficiency in producing high-quality coatings rapidly; unmatched uniformity through ion exchange membrane technology; precise controllability of thickness, hardness, and morphology; environmentally friendly processes with minimal emissions; versatile application across different metal coatings and colors; and outstanding cost-effectiveness compared to traditional plating methods. EIDORADO's comprehensive design includes corrosion-resistant electroplating tanks, advanced ion exchange membranes, optimized electrode configurations, reliable power supplies, accurate temperature control systems, and intelligent automation features that together deliver world-class surface treatment solutions.