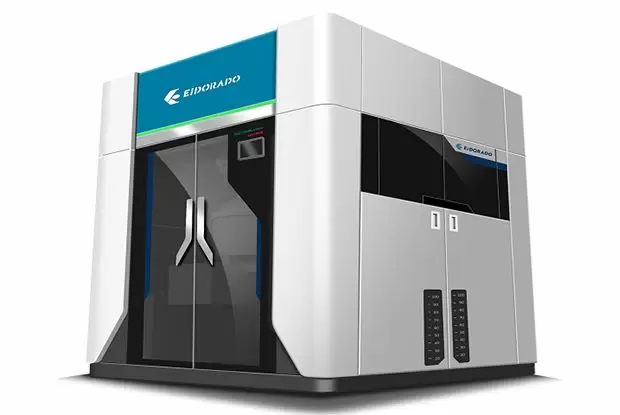

Continuous Plating Equipment

Continuous electroplating equipment is developed and manufactured by EIDORADO CORP continuous electroplating engineers with more than 20 years of experience. Only those with experience in operating equipment can create convenient and reliable equipment. Our company has rich knowledge and technology, and can achieve optimal control and management of production speed and current to ensure the stability of production.

More efficient electroplating method, professionally used strips and terminals.

Equipped with a variety of different abilities such as immersion, printing, spraying, and precision cutting.

Special features of precious metals, spray selection plating tools, and conductive fast differential fixing properties.

Kasakuto 4-line selection electric baton.

Product Features

- High Efficiency: Continuous electric plating equipment can actually be continuously produced, and can be used in a short period of time to produce large quantities of products. The product can be used in a large amount, with high efficiency and high efficiency.

- Consistency: Continuous electrical equipment automation control system can monitor and adjust the number of individual work stations, and ensure the consistency of products. Species concordance is ensured for each individual product, and the variation in production is reduced.

- Savings: Continuous electric plating equipment can actually produce automation, reduce artificial connection, and reduce power consumption. At the same time, the continuous electrical plating equipment can be used to produce large quantities of products, so it is possible to produce a large amount of products, and the production of low-volume products can be achieved.

- Environmental Protection: Continuous electroplating equipment usually uses low-staining electroplating liquid, which reduces environmental impact. At the same time, continuous electricity equipment can actually achieve high efficiency in metal utilization, reduce waste and eliminate waste, and further improve environmental protection.

Mechanism Design

The structural design of continuous electroplating equipment usually includes the following aspects:

1. Pre-treatment Area: The pre-treatment area of continuous electroplating equipment usually includes cleaning, pickling, alkali cleaning and other processes to remove surface dirt and oxide layers to ensure the electroplating effect.

2. Electroplating Area: The electroplating area of continuous electroplating equipment usually includes processes such as electroplating tank, cooling area and drying area. In these processes, metal ions are reduced in the plating solution and deposited on the surface of the object to be plated to form a metal layer.

3. Post-processing Area: The post-processing area of continuous electroplating equipment usually includes washing, drying, packaging and other processes to ensure the quality and appearance of the product.

4. Automatic Control System: The automatic control system of continuous electroplating equipment usually includes PLC control system, human-machine interface, electroplating solution circulation control system, etc., to realize automatic control and monitoring of equipment.

5. Equipment Rack: The rack of continuous electroplating equipment is usually made of stainless steel to improve the durability and stability of the equipment.

To sum up, the mechanism design of continuous electroplating equipment is complex and needs to consider various process requirements and the design of automated control systems. Excellent design can improve the production efficiency, product quality and stability of equipment, thereby bringing greater benefits to industrial production.

Application

Continuous plating equipment is widely used in a variety of industries, including electronics, automotive, aerospace, home appliances, construction and food.

The following are the applications of continuous electroplating equipment in various industries:

1. Electronics: Continuous plating equipment can be used to produce metallization treatments for electronic products such as printed circuit boards, integrated circuits, and conductive adhesives.

2. Automobile: Continuous electroplating equipment can be used to produce automobile parts, such as wheel hubs, aluminum alloy frames, doors, windows and other surface treatments.

3. Aerospace: Continuous plating equipment can be used to produce surface treatments for aerospace components, such as engine parts, fuselage structural parts, etc.

4. Home Appliances: Continuous electroplating equipment can be used to produce surface treatment of home appliances, such as refrigerators, washing machines, televisions and other products.

5. Construction: Continuous electroplating equipment can be used to produce surface treatment of building materials, such as aluminum plates, steel structures, etc.

6. Food: Continuous plating equipment can be used to produce surface treatments for food processing equipment, such as food plates, tableware, etc.

In short, continuous electroplating equipment has a wide range of applications, which can meet the surface treatment needs of different industries, improve product quality and performance, and provide technical support for industry development.

How Can Continuous Electroplating Increase Your Electronics Production Throughput?

EIDORADO's continuous electroplating systems can transform your production capacity, enabling you to process large volumes of electronic components with consistent quality in significantly less time. Our customers typically report 40-60% increased throughput compared to traditional batch plating methods, with automated controls ensuring uniform metal deposition across all products. Contact us for a customized assessment of how our continuous plating equipment can optimize your specific manufacturing processes.

Our continuous electroplating systems excel in efficiency, consistency, cost-effectiveness, and environmental protection. The fully automated control system monitors and adjusts individual workstations to guarantee product uniformity while significantly reducing labor requirements and power consumption. EIDORADO's equipment utilizes low-contamination electroplating solutions that minimize environmental impact while achieving superior metal utilization rates. The robust stainless steel construction ensures durability in demanding industrial settings, making our continuous plating equipment the preferred choice for electronics, automotive, aerospace, and other precision manufacturing industries requiring high-quality surface treatments.