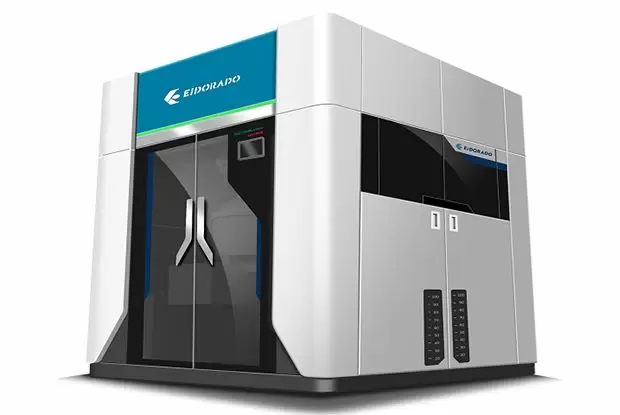

Electroplating Equipment

The patent developed by EIDORADO CORP specifically for this problem uses a special turning mechanism to completely discharge the water in the depressions of the plated object to achieve the best cleaning effect, reduce waste water discharge and reduce costs.

Generally speaking, electroplating equipment has certain pollution, which needs to be avoided whether it is for the environment or the enterprise. Using our company's energy-saving and emission-reduction plan, we can significantly reduce the emission of waste water and waste gas. The most common problem of hanging plating with a flip mechanism is that the plated object has cup-shaped depressions, which causes the chemicals in the plating tank to be brought to the washing tank, causing unnecessary waste. What is even more troublesome is that different chemical solutions are brought to other chemical tanks. , making it less effective or unusable and thus increasing costs.

Product Features

- Efficiency: Electroplating is an efficient surface treatment method that can form a uniform, dense, and smooth metal coating in a short time.

- Accuracy: By controlling the parameters of electroplating equipment, parameters such as plating solution concentration, temperature, voltage and current can be accurately adjusted to obtain the required coating thickness and quality.

- Applicability: Electroplating can be plated on the surface of various materials, including metals, non-metals and plastics, and can produce metal coatings of different types and colors.

- Environmental Protection: Compared with other surface treatment methods, such as spray painting, electroplating has smaller pollutant emissions, and can reduce environmental impact by recycling the plating solution and using environmentally friendly plating solutions.

Institutional Design

The structural design of electroplating equipment will be designed according to the characteristics of different plating solutions and objects to be plated. The following are some common elements in the mechanical design of electroplating equipment:

1. Plating Tank: The plating tank is a container that holds the object to be plated and the plating liquid. It can be made of stainless steel, plastic or glass. The shape and size of the plating tank will be designed according to the shape and size of the object to be plated.

2. Plating Solution Stirring System: The plating solution stirring system can ensure the uniform distribution of metal ions and additives in the plating solution to achieve better coating quality. The stirring system can be mechanical stirring or bubble stirring, or a combination of the two.

3. Power Supply System: The power supply system includes DC power supply, AC power supply, rectifier, transformer and other components to provide the required current and voltage. Typically, a DC power source is preferred because it produces uniform deposition rates and coating thicknesses.

4. Anode and Cathode: Anode and cathode are the two electrodes in electroplating equipment. Through the electrolyte between the anode and cathode, metal ions can be reduced and deposited on the object to be plated. Typically, the object being plated serves as the cathode, and the metal plate or strip serves as the anode.

5. Electrolyte Circulation System: The electrolyte circulation system is used to control the temperature, concentration, pH value and other parameters of the plating solution to maintain a stable plating solution state. The circulation system includes pumps, filters, heaters and other components to ensure the uniformity and stability of the plating solution.

6. Control System: The control system is used to monitor and adjust the parameters of the plating solution, including current, voltage, temperature, concentration, etc. Usually, the control system adopts automatic control such as computer or PLC.

Application

1. Electronics Industry: The electronics industry requires high-precision metal plating for circuit boards, IC packaging, conductive wires and other products. Electroplating equipment can produce high-precision coatings that meet the needs of these products.

2. Automotive Manufacturing: The automotive manufacturing industry requires a protective metal layer on auto parts to prevent corrosion and wear. Electroplating equipment can coat this protective metal layer, extending the life of auto parts.

3. Jewelry Manufacturing Industry: The jewelry manufacturing industry requires a layer of exquisite plating on metal jewelry, such as gold, platinum, etc. Electroplating equipment can produce high-quality coatings that increase the value and beauty of jewelry.

4. Aviation Manufacturing Industry: The aviation manufacturing industry needs to coat aircraft parts with a metal layer of high strength and high corrosion resistance to improve their safety and lifespan. Electroplating equipment can plate this high-strength and highly corrosion-resistant metal layer.

5. Food Packaging Industry: The food packaging industry needs to coat packaging materials with a metal layer to improve their freshness and aesthetics. Electroplating equipment can apply this metallic layer to make packaging materials more attractive and functional.

Overall, electroplating equipment is widely used in various industries to produce metal coatings with high precision, high quality, high corrosion resistance and high aesthetics.

What Makes EIDORADO's Electroplating Equipment Essential for Semiconductor Manufacturing?

Semiconductor manufacturing demands unprecedented precision and consistency. EIDORADO's electroplating equipment features advanced control systems that precisely adjust plating solution concentration, temperature, voltage, and current to achieve exact coating specifications. Our clients in the semiconductor industry report 99.8% consistency in coating thickness and quality, with significant reductions in rework and material waste. The integration of our patented technologies ensures both production excellence and environmental responsibility—critical factors in today's competitive semiconductor market.

Our electroplating systems combine precision engineering with environmental responsibility, offering high-efficiency automation and accurate processing capabilities. Each unit is meticulously designed with sophisticated plating tank configurations, advanced solution stirring systems, precision power supply controls, and intelligent electrolyte circulation systems. EIDORADO's equipment delivers uniform, dense, and smooth metal coatings across various materials while minimizing environmental impact through reduced pollutant emissions and environmentally friendly plating solutions, making our technology the preferred choice for forward-thinking manufacturers in electronics, automotive, aerospace, and other precision industries.