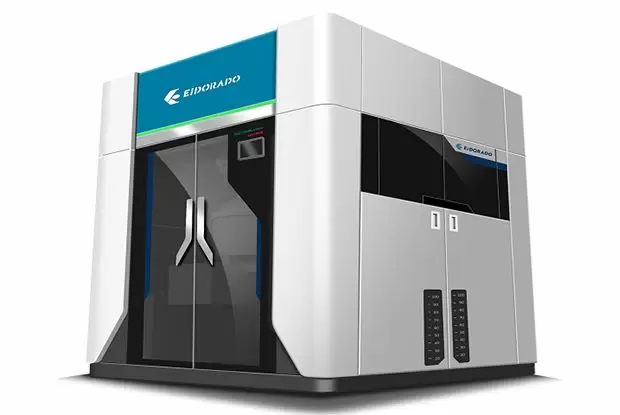

Electroplating Experimental Equipment

EIDORADO CORP electroplating experimental equipment has high electroplating efficiency. Compared with competitors in the application field, it has stable rectifier current output, is equipped with a paperless process monitoring and recording system, and is connected with MES system data to achieve the goal of Industry 4.0. efficiency.

Surface treatment can be performed with lower material cost and better thickness uniformity. All processes are based on energy-saving and environmentally friendly processing technology, and customized forms meet customer needs.

Product Features

The electroplating experimental equipment can select available slots according to actual needs to meet a small number of diverse testing needs. The tank body is designed in a master-sub-tank design. Each process time, voltage and current can be set to the most appropriate parameters according to needs. Up to 7 sets of parameters can be set at the same time, so no waiting time is wasted, and product quality can be monitored at any time. The current of each substrate can be set independently; and based on multi-band settings, the uniformity of the metal layer can be improved. It can be used for manual mass production or insertion of single samples; the sample and mass production can be carried out at the same time. The On Line voltage is equipped with an overvoltage alarm function to detect abnormalities. The flying target and hanger are designed and manufactured in a consistent manner with good conductivity efficiency.

● Precision Control: Electroplating experimental equipment usually has a precise control system that can control the concentration, temperature, flow rate and other parameters of the plating solution to ensure the stability and uniformity of the coating quality.

● Efficient Performance: The design of electroplating experimental equipment can usually provide efficient coating production and produce high-quality coatings in a short time.

Versatility: The electroplating experimental equipment can perform a variety of plating, such as gold, silver, copper, nickel, zinc and other materials, as well as a variety of base materials of different shapes and sizes.

● Environmental Protection and Energy Saving: Electroplating experimental equipment usually has the characteristics of energy saving and environmental protection, which can effectively reduce the waste and pollution of plating solution, while reducing the burden on the environment.

● High-precision Control: Electroplating experimental equipment usually has a high-precision control system, which can achieve high-precision coating thickness control to meet the needs of different applications.

Institutional Design

1. Plating Solution Tank: Used to hold electroplating solution, generally made of plastic, glass and other materials.

2. Power Supply: Provides power for the plating process, which can be DC or AC power, depending on the plating material.

3. Electrode: Used to pass electric current in the electroplating solution, usually including an anode and a cathode.

4. Mechanical Stirring Device: Used to stir the plating solution to maintain uniform concentration of substances in the plating solution.

5. Cleaning Device: Used to clean the surface of materials before plating, usually including degreasing, decontamination and other steps.

6. Immersion Tank: Used to soak materials before plating to remove surface oxides and other impurities.

7. Monitoring System: Used to monitor current, voltage, coating thickness and other parameters during the electroplating process.

8. Collection Tank: Used to collect excess plating solution to avoid environmental pollution.

The above are some common electroplating experimental equipment. The actual equipment can be adjusted and changed according to experimental needs.

Application

1. Metal Processing Industry: It is widely used in the metal processing industry and can be used to clean and treat metal parts, tools, machines and other products, thereby improving their surface quality and corrosion resistance and enhancing their mechanical properties.

2. Electroplating Industry: It can be used for surface treatment before electroplating to improve the adhesion and uniformity of electroplating by removing dirt and oxide layers on the metal surface, making the electroplated layer more stable and durable.

3. Automotive Industry: It can be used for surface treatment of auto parts to improve their quality and corrosion resistance, enhance their mechanical properties, and ensure the safety and reliability of the car.

4. Aerospace Industry: It can be used for surface treatment of aerospace parts to improve their surface quality and corrosion resistance, enhance their mechanical properties, and ensure the safety and reliability of aerospace vehicles.

5. Food Processing Industry: It can be used in the food processing industry to clean and disinfect stainless steel containers, pipes, equipment, etc., thereby ensuring food safety and hygiene standards.

What makes an electroplating system ideal for diverse R&D applications?

Research and development laboratories require exceptional versatility in electroplating equipment—exactly what EIDORADO delivers. Our experimental systems allow you to select available slots according to specific testing needs, with each process time, voltage, and current independently configurable. The ability to set up to 7 parameter sets simultaneously means you can conduct multiple experiments without delays. Whether you're working with gold, silver, copper, nickel, zinc, or other materials, our equipment handles diverse base materials of various shapes and sizes. The combination of precision control, versatility, and detailed monitoring capabilities makes our systems the preferred choice for cutting-edge electroplating research. Contact our technical team to discuss your specific R&D requirements.

What sets our equipment apart is the seamless integration with Industry 4.0 standards through our paperless monitoring system and MES connectivity. The versatile design accommodates both manual mass production and single sample insertion simultaneously, with built-in overvoltage alarm functions for enhanced safety. Our environmentally conscious approach incorporates energy-saving processing technologies without compromising performance. From precision control of solution concentration and temperature to efficient mechanical stirring and comprehensive monitoring systems, EIDORADO's electroplating experimental equipment delivers the reliability, versatility, and environmental sustainability demanded by today's advanced manufacturing environments.